Each day, the United States uses more than 161 billion gallons of water to cool factories, server farms and power plants. Power plant cooling is one of the largest economic necessities in the world, and yet, College of Engineering Professor Young Cho says many plants are using decades-old methods.

In 1990, Cho began studying how to modernize and streamline cooling systems. When a power plant produces energy, it also produces heat. The solution for the past 100 years has been to dump that heat by evaporating water.

Problem is, every time water evaporates, a layer of minerals is left behind on machinery that makes the process less efficient on the next run.

For years, Cho looked for a way to reduce that scaling. He knew that many plants used chemicals to treat their water, and he wanted to move away from that.

“People use chemicals to solve a chemical problem,” he says. “It just creates another chemical problem.”

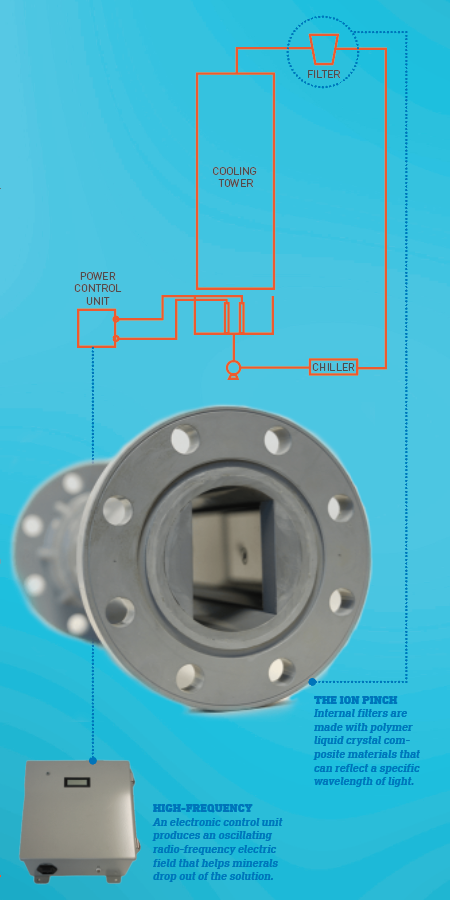

He toyed with putting magnets in the water, running an electric coil around the cooling tubes, but in the end, he found that the best method was simply to put two charged plates in the tube, running an electric field though the water. This way, the minerals in the water would collide more and create large, soft matter that could be extracted.

He had the concept down by the early 2000s and a patent by 2007, but didn’t know how, nor have the time, to commercialize the idea. So he called up his entrepreneur son, Dan Cho.

In 2016, Dan Cho helped license the technology from Drexel and form what is now Onvector, a King of Prussia-based company where he is CEO and his father is chief scientist.

Young Cho, inventor

He also brought on their business-minded president, and Drexel alum, Joe Henderson (BS computer science ’85). Their wastewater treatment product is called Ion Pinch.

“I really appreciate Dan’s involvement,” Cho says. “As a professor, I’ve been a prolific inventor, but there’s no chance for me to do commercialization. In a sense, he is making a sacrifice for me.”

Last year, the team proved its concept with a field test of Ion Pinch at Drexel’s Korman Center. The installation saved the center $7,000 that year and increased efficiency 11 percent, saving not only money, but water and energy.